Your key

challenges

Materials face many external stresses which in some cases affect their performance and stability. From manufacture to operation of the final product, it is essential to ensure the conformity of the materials used and compliance with the standards and obligations in force, and to control the risk of failures.

- Test and qualify your equipment, products or materials to ensure their conformity and robustness

- Obtain certificates for CE marking to guarantee the compliance and safety of goods circulating within the European Union

- Use materials compatible with the final use of the product

- Study the behaviour of the material in various situations

- Assess the quality and safety level of the material

- Ensure compliance with the regulatory standards associated with the material used

- Test your mobile network quality and equipment, implement your own 5G private network, ensure the best end-user experience and technology leadership

Did you know ?

The complete Apave offer

to respond to your challenges

- Destructive testing/non-destructive testing

- Mobile networks testing and optimizing

- Chemical analysis (on-site or in a laboratory)

- Mechanical, metallographic tests, etc.

- Strength calculations

- Expertise

- Training

- CE marking

You build, operate or maintain equipment made of metal materials

You wish to check the characteristics of the materials in the context of material acceptance, in the context of qualification of welding procedures or welders, or in the context of repairs with the aim of guaranteeing the safety of the equipment:

- Qualification of materials or welds: tensile strength, hot tensile strength, bending, resilience, macro and micrographic examinations, hardness tests, chemical analyses, corrosion tests,

- Custom tests (compression, heat treatment, etc.)

- Damage analysis: wear, breakage, corrosion

- Semi-quantitative chemical analysis (PMI)

- Microscopic examination by installation of metallographic replicas

- Hardness tests (Leeb, Micro Vickers)

- Ferrite content measurement (ferritescope)

- The test laboratory is COFRAC ISO 17025-accredited and meets the new requirements of the nuclear industry (FRAMATOME, EDF customer specifications, etc.)

You build or operate equipment made of composite materials or thermoplastics

You occasionally wish to check the characteristics of this equipment and qualify the assembly procedures as well as the personnel involved.

- Qualification of procedures, welding, laminating and bonding personnel (according to NF T 57900, NF EN 13121, NF EN 13067, etc.)

- Micro and macrographic examinations

- Physico-chemical tests

- Mechanical tests on control samples (tensile strength, bending, compression, interlaminar shear strength)

- Special tests on request

You work at (hazardous and household) waste storage facilities

You have to carry out checks to ensure the safety of people and the environment:

- Checks of geomembrane properties

- Welding tests

- The laboratory is approved by ASQUAL for tests on this type of product

You want to check your new equipment before shipping

Apave's teams work closely with our clients to provide pre-shipment inspection services that best meet their needs, complemented by supplier audit services. Our experienced and qualified teams, with industry-specific knowledge and expertise, can help you ensure the quality and reliability of your products, equipment and materials. Our pre-shipment inspection services are tailored to your specific needs:

- Ensure the quality of your products, equipment and materials before they are shipped from the manufacturer

- Assist with mechanical testing

- Factory acceptance testing

- Hydrostatic testing

- Performance testing

- ASME certification

- Canadian Registration Number (CRN)

- American Petroleum Institute (API) certifications

- ATEX Directive

- Indian Boiler Regulations (IBR) certifications

- Singapore Product Registration (MOM)

- Malaysia Product Certification (DOSH)

- Local Content certifications (Brazil)

Learn more about pre-shipment inspection of new equipment

Learn more about pre-shipment inspection of new equipment

You wish to market products in the European Union and need to obtain CE marking

To meet regulatory requirements and certify the compliance of your products to guarantee the safety of users:

- PPE to protect against falls from height, APR respiratory protection equipment, helmets, etc. To obtain the associated certification programmes, please contact our Fontaine Laboratory

- Computer hardware and laboratory and testing equipment

- Electrical appliances and low voltage industrial appliances

- Lifts and safety components for lifts

- Pressure equipment

- Tests for CE marking

- Assessment of electrical products in the context of CB certification for international use

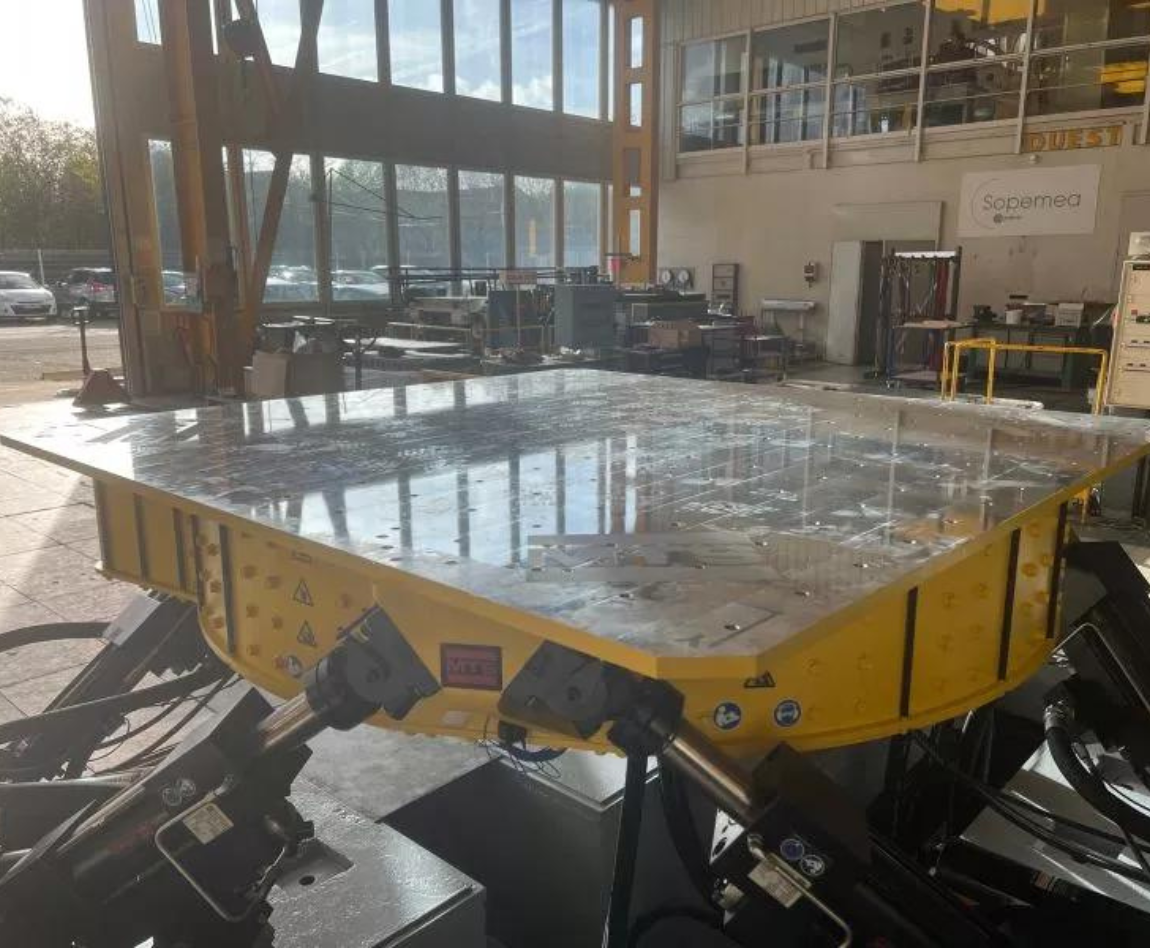

Sopemea for the qualification of your equipment

Why choose

Apave ?

TRUST

EXPERTISE

COMMITMENT

On the same

topic

Our

support