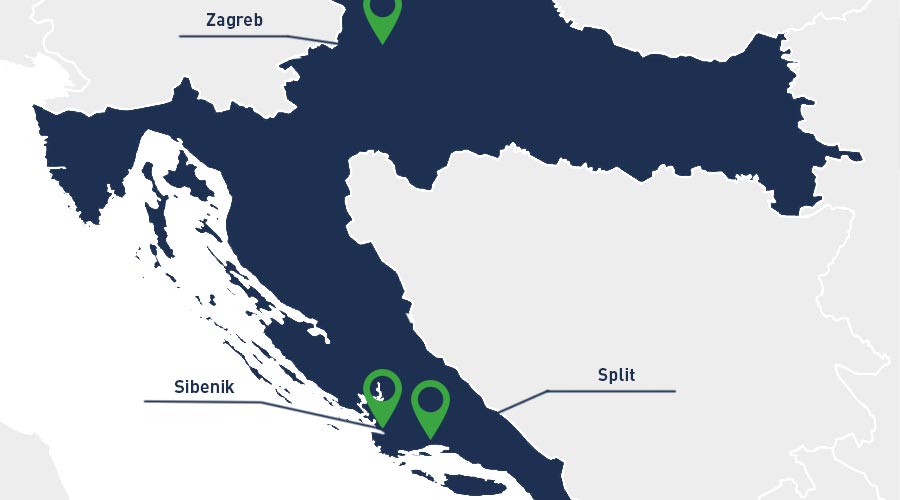

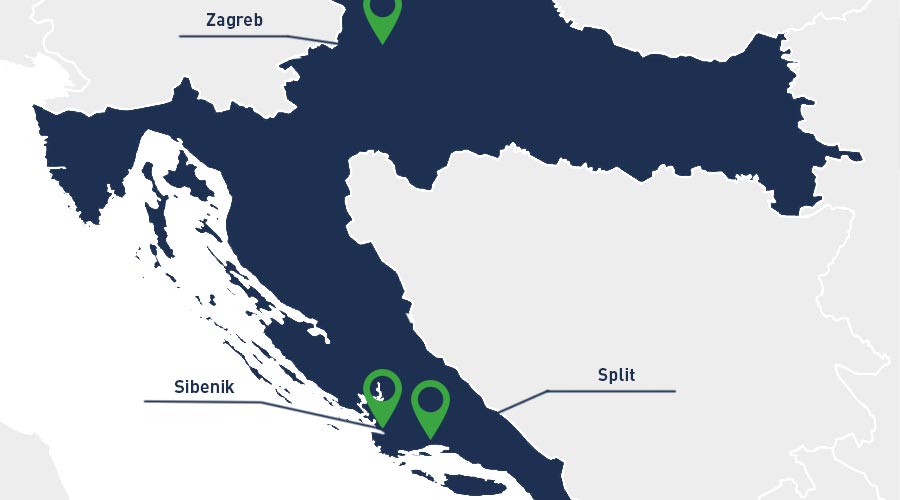

Apave Mare Regional Office

![]() Milutina Baraca, 19 - 22000 - SIBENIK

Milutina Baraca, 19 - 22000 - SIBENIK

![]() 385 22 201 175

385 22 201 175

Apave Mare Training Center Split

![]() Kopilica 62 - 21000 - SPLIT

Kopilica 62 - 21000 - SPLIT

![]() 385 21 485 730

385 21 485 730

Apave Mare Training Center Zagreb

![]() Zaharova ulica 7 - 10000 - ZAGREB

Zaharova ulica 7 - 10000 - ZAGREB

![]() 385 1 389 9970

385 1 389 9970

Check facilities and equipment

We check the reliability of your installations, equipment, structures, infrastructures and buildings, to keep them in compliance when they are commissioned and during operation.That's why Apave is the partner of choice for regulatory and non-regulatory inspections.

Equipment compliance

- Inspecting electrical installations: fixed or temporary, in the workplace or at home.

- Inspect pressure equipment: generators, tanks, piping, autoclaves.

- Explosive Atmosphere Inspection (ATEX)

- Check lifting devices and mechanical equipment.

- Check radiological protection of X-ray equipment.

- Check scaffolding for correct assembly and safety.

- Periodically check dangerous machines.

- Check lightning protection systems.

- Check transport of dangerous goods.

- Check heating and air-conditioning systems.

- Check equipment emitting non-ionizing radiation: lasers, ultraviolet devices, artificial optical radiation, electromagnetic fields.

- Check thermal installations: boilers and air-conditioning systems.

- Inspect buried pipes to identify critical points.

- Check the cathodic protection of hydrocarbon pipelines.

- Check equipment emitting non-ionizing radiation: lasers, ultraviolet devices, artificial optical radiation, electromagnetic fields.

Use new technologies in complete safety

- Check machine conformity and work in co-activity with cobots.

- Check heating and air-conditioning systems.

- Check equipment emitting non-ionizing radiation: lasers, ultraviolet devices, artificial optical radiation, electromagnetic fields.

Check the quality and design of equipment and materials.

- Check the correct installation of communication networks: fiber optics and mobile telephony.

- Check the design of nuclear pressure equipment.

- Check the quality of welding operations.

- Carry out mechanical and destructive tests to validate a manufacturing process.

- Carry out non-destructive testing (Phased Array ultrasound, Floorscan MFL, ACFM, TOFD, etc.).

Inspect ERP (Etablissement Recevant du Public) installations.

- Check electrical installations for outdoor lighting: traffic lights, public lighting, sports stadium lighting.

- Inspect automatic and semi-automatic doors and gates.

- Inspect sports facilities and children's playgrounds.

- Check fire-fighting systems: alarms, emergency equipment, SSI, sprinklers, etc.

- Check fuel gas installations.

- Check elevators, freight elevators, escalators, moving walkways.

Ensuring the performance, safety and sustainability of your processes, equipment, utilities and facilities

- Multi-directive compliance.

- Assessment of occupational and QHSSE risks.

- Loss of operation or asset value.

- Project management assistance for successful industrial projects (from needs analysis to performance acceptance).

- Reliability, safety and availability (operating safety - FMDS - TPM - supervision).

- Technical health check, life cycle extension, full cost management.

- Improving yields and production costs.

- Improving maintenance performance.

Train your teams

Our expert trainers can help you improve your teams' skills. At Apave, we specialize in technical training related to health and safety. We offer a wide range of training courses to meet your skills development needs, both locally and internationally. To help you make the right choice, we've put together a number of catalogs for you to download according to your criteria: discover all the training courses available, identify those suited to your sector of activity, or explore online training courses.

- Asbestos

- Explosive atmospheres (ATEX)

- Building & civil engineering

- Lifting & Handling

- Electromagnetic compatibility

- Scaffolding

- Electricity

- Energy and energy transition

- Environment, quality and industrial risks

- Equipment under pressure (ESP)

- Fire

- Electric mobility

- Nuclear

- Production Industrial Maintenance

- Radiation protection PCR

- Digital risks, security and malicious acts

- Occupational health and safety

- Welding Non-destructive testing (NDT)

- Transport of Dangerous Goods (TDG)

- Working at height

Maintain health and safety at work

Today's companies face increasingly complex and evolving health and safety challenges. To meet these challenges, it is essential to develop a culture of risk prevention within the company.

At Apave, we are convinced that taking health and safety at work into account is a performance driver for the company. Indeed, reducing the number of workplace accidents and occupational illnesses has a direct impact on absenteeism rates, and the direct and indirect costs to the company of absent employees. Apave can help you integrate the health and safety dimension as a corporate value, in the same way as production or quality.

At Apave, we are convinced that taking health and safety at work into account is a performance driver for the company. Indeed, reducing the number of workplace accidents and occupational illnesses has a direct impact on absenteeism rates, and the direct and indirect costs to the company of absent employees. Apave can help you integrate the health and safety dimension as a corporate value, in the same way as production or quality.

Improve public and worker health and safety

- Develop your health and safety culture: diagnostics, operational support, training, health and safety leadership.

- Improve the performance of your risk management tools: outside contractors, transport of dangerous goods (TDG), consignment of all fluids, ATEX, fire...

- Implement effective, operational management systems: MASE, ISO 45001, worksite risk management for new construction or process work, etc.

Control and improve human and organizational performance

- Consulting in people and business management, governance and change management.

- Skills development, workplace performance.

- Performance and resilience of organizations and processes, management systems.

- Problem-solving, progress projects and continuous improvement, via prevention plans.

- Management of external contractors: diagnostics, support, field follow-up, training, creation of tools, on-site management.

Testing and qualifying your equipment

Testing and qualifying your equipment, products or materials is essential to guarantee their conformity and robustness in the face of the external constraints they may encounter. Whether you're processing, operating or marketing your product, it's vital to ensure compliance with current standards and obligations, and to control the risk of failure.

Thanks to our tests, we can help you qualify your products and equipment and obtain the necessary certifications, thus guaranteeing the conformity and safety of your assets. We study the behavior of your materials in a variety of situations, and offer a wide range of services from destructive testing to non-destructive testing (NDT), including chemical analysis on site or in the laboratory, mechanical and metallographic testing, strength calculations...

Thanks to our tests, we can help you qualify your products and equipment and obtain the necessary certifications, thus guaranteeing the conformity and safety of your assets. We study the behavior of your materials in a variety of situations, and offer a wide range of services from destructive testing to non-destructive testing (NDT), including chemical analysis on site or in the laboratory, mechanical and metallographic testing, strength calculations...

Conformity assessment and CE and UKCA marking of products and equipment

- Personal protective equipment (PPE)

- Gas appliances

- Pressure equipment

- Elevators

- Lifting equipment

Industrial testing and material characterization

- Conformity and assessment of Electrical Products for international CB certification

- Qualification of welding materials and procedures

- Climatic testing

- Mechanical, metallographic and other tests

- EMC testing

- Hydraulic testing

- Calibration control

- Destructive testing / non-destructive testing,

- Chemical analysis of materials,

- Strength calculations,

Carrying out environmental sampling

Environmental sampling

- Measurements of atmospheric emissions (emission measurements, fallout measurements, QAL2 and AST tests) and water sampling and analysis (industrial effluents, rainwater, surface water, groundwater),

- Measurements of environmental noise levels.

- Taking soil pollution into account

Indoor air quality control

- Measurements of exposure to noise and vibration,

- Measurement of exposure to pollutants in the workplace,

- Ventilation controls (sanitation of workplaces),

- Indoor air quality assessments in ERP buildings.

Our News